Spock is arguably one of the most well-known science officers of the starship Enterprise. His mixed human-Vulcan heritage makes him unapologetically truthful in all things. When we consider what he might say about the versatility of wooden containers we know its highly illogical that he would lead us astray.

Take a look at 3 things this omniscient being would say about wooden containers.

1. “Live long and prosper”

When Spock says, live long and prosper, he must be talking about the remarkable life expectancy of wooden containers. If you treat them right, these resilient containers can last for years.

When Spock says, live long and prosper, he must be talking about the remarkable life expectancy of wooden containers. If you treat them right, these resilient containers can last for years.

- All you have to do is keep moisture low and consider installing special sheets or covers. It’s also a good idea to utilize desiccants, moisture-absorbing technology, and other anti-corrosion methods.

- Add some eye-popping paint and your wooden crate will last even longer. You see, paint of any kind will form a moisture-impervious film while keeping the seal at wood junctures intact.

2. “Change is the essential process of all existence"

When it comes to wooden containers and your supplier, it’s important to constantly evaluate both in order to identify any small changes that could lead to big improvements. With emerging technologies every year, you will always have a chance to improve upon your packaging design.

When it comes to wooden containers and your supplier, it’s important to constantly evaluate both in order to identify any small changes that could lead to big improvements. With emerging technologies every year, you will always have a chance to improve upon your packaging design.

Here are a few tips to keep design advancements moving forward:

- Have ongoing reviews, which provide a benchmark for evaluations of safety, performance, alternative packaging solutions, and cost savings.

- Provide your packaging supplier with drawings, pictures, and dimensions of your product to ensure ongoing success and savings.

- At the end of the package's lifecycle, evaluate the performance of the packaging. This may lead to a redesign consideration for continued improvement.

- Continue to evaluate the packaging company’s prices as well as efficiency and level of quality and customer service.

- Install damage indicators that can help you evaluate how your products are being handled.

3. "Humans do have an amazing capacity for believing what they choose and excluding that which is painful"

Wow, pretty heavy-duty huh? But it had to be said. Damages to shipments can happen. What’s worse is, resolving them can be a truly painful process. No matter what you do though, don’t just sweep it under the rug. It can only get worse. Face damages head-on to keep one bad run from turning into two, then three, and so on. You can also take proactive steps to prevent damages in the first place.

Wow, pretty heavy-duty huh? But it had to be said. Damages to shipments can happen. What’s worse is, resolving them can be a truly painful process. No matter what you do though, don’t just sweep it under the rug. It can only get worse. Face damages head-on to keep one bad run from turning into two, then three, and so on. You can also take proactive steps to prevent damages in the first place.

Here’s how:

- If there are handling, transport, and unpacking procedures, include visual instructions on the outside of the package.

- Evaluate your distribution environment and possible variables associated with land, sea, air, or rail transport. Is there anything you can change?

- Take a photo of the packaged product prior to shipment and indicate this with the shipment. This may prove to be an excellent deterrent.

- If you suspect that the carrier is mishandling your shipments, include damage indicators that can provide evidence to support a damage claim that products may have become damaged during transit.

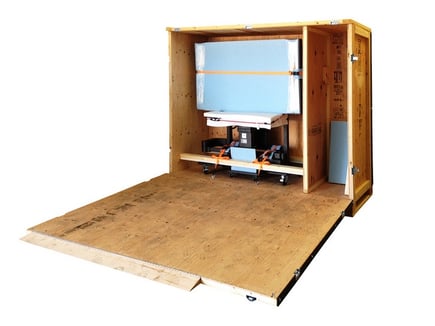

- Don’t try DIY to save a buck. Valley Box has on-site packaging services where expert packaging technicians have the knowledge, experience, equipment, and materials to package your product properly (the first time) and in a timely manner.

Well said, Spock!