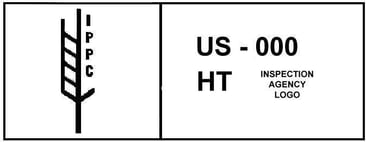

Heat treated wood bearing the ISPM 15 stamp is mandatory for overseas shipments with wood outer packaging. This came from the need to control plant diseases worldwide and compliance with the US Department of Agriculture.

Heat treatment is a non-chemical process to prevent the international transport and spread of disease and insects that could negatively affect plants or ecosystems. The process involves heating the wood material until its core reaches 56 °C or 132.8°F for at least 30 minutes. This process ensures that all materials are treated thoroughly and not just the surface. The thermal modification of wood significantly improves its resistance to rot and fungal decay.

The Heat Treatment Program was developed in order for the American Lumber Standard Committee to implement a quality control program for the official labeling of heat treated wood packaging material with the ISPM 15 stamp official mark.

Plus exporters face consequences for non-compliant wood products. If the lumber used on an overseas shipment does not bear the official mark there could be a hold-up in customs and potential liability. For those of you familiar with customs inspections, the last thing you want is for your product to be waiting in port.

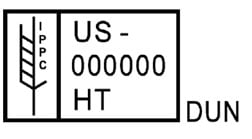

Companies who export their products overseas sometimes require loose lumber, otherwise known as dunnage. It's used in conjunction with the wood shipping crate to restrict the movement of the internal products or to keep the crate static during transit. Generally dunnage is just reused pieces of lumber, however if a customs official inspects the inside of the crate, each piece of dunnage must bear the "DUN" ISMP 15 stamo for heat treatment. Also keep in mind dunnage stamped lumber cannot be used on the exterior of the crate.

Case Study: ISPM 15 stamp

In this case study an Import Export company was experiencing long wait times during customs inspections. The container was not easily opened for verification and the vapor barrier bag was left open exposing the sensitive machinery to atmospheric moisture resulting in corrosion damage.

By installing an observation/inspection port on the exterior wood container, and a viewing port in the barrier bag, we allowed customs to perform their tasks without breaching the seal or the container. A humidity indicator visible through the observation port was also added. This provided a method to confirm the integrity of the vapor barrier bag.

This observation port design successfully reduced damage claims to zero and expedited all future customs inspections.