At Valley Box we're constantly striving to find new technologies to improve or enhance our wooden crates. We created a video showing our latest improvement involving a heavy duty wooden crates base, built to carry loads in excess of 50,000 pounds. Check the video out below!

Traditionally, Valley Box uses a carriage-bolt assembly (12" carriage bolt + washer+nut) in order to reinforce the strength at the 4 corners on the heavy duty bases of our wooden crates.

Recently Simpson Strong-Tie® introduced us to their alternative fastener, the 12” SDWH Timber-Hex HDG screw.

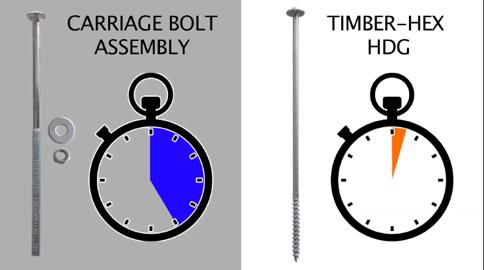

When we compare the construction requirements for a carriage-bolt assembly to the Timber-Hex HDG screw, we can see an immediate labor savings.

The original design requires several steps in order for the construction to be complete:

- First the wooden crates base is sub-assembled and pre-drilled with a ship auger bit

- Then the base must be flipped over, using two forklifts to safely transition the heavy base, in order for the bottom side to become more accessible

- Then a recessed hole is drilled with a fly bit

- The ½” carriage-bolt is slipped into the pre-drilled hole, the washer is added, followed by the nut which is tightened with an impact wrench

- These fasteners sandwich the material together creating unbelievable strength.

The construction process using the Simpson Strong-Tie® Timber-Hex HDG screw is much faster. The screw has a SawTooth™ point and oversized integral washer.

- The screw is simply installed with a ½” low-speed drill through all layers of material. The SawTooth™ point design results in a fast start and does not require pre-drilling.

But we were curious if using the TIMBER-HEX HDG screw would be comparable to the strength of the carriage-bolt assembly. So we traveled to the Simpson Strong-Tie® testing facility in Riverside California to put these two fasteners to the test in a state-of-the-art strength testing vertical rig capable of exerting 100,000 lbs.

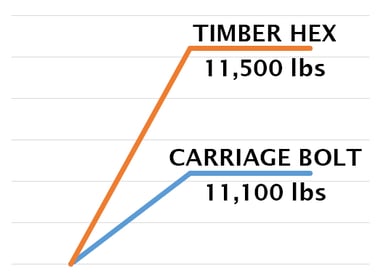

First, Simpson Strong-Tie® technicians loaded a base cutaway, utilizing the carriage-bolt assemblies, into the vertical testing rig. The rig exerted a downward load rate at .2 inches per minute. The strength of the carriage-bolt assembly was measured. The resulting load was divided by 4 to calculate the strength of each corner assembly.

- The washer, in the carriage-bolt assembly, is the component that failed at around 11,100 lbs per bolt.

The base cutaway is removed and replaced with a cut away model using the Timber-Hex HDG screws. Again load rate is applied at .2 inches per minute.

- The threads of the Timber-Hex screw pulled through the wood at around 11,500 lbs per screw.

Each cutaway is run through the vertical rig twice and the results are quite impressive with the Timber-Hex HDG screw outperforming the carriage-bolt assembly in each test.

This proves that the Simpson Strong-Tie® Timber-Hex HDG fastener offers superior holding strength when compared to the carriage-bolt assembly.

Valley Box is constantly on the lookout for new technologies to help improve the strength and performance of our wooden crates to assure that your product gets to its destination in perfect condition.