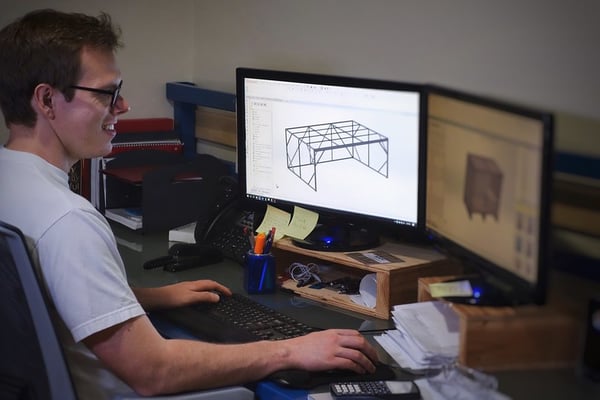

Valley Box Company, a Southern California industrial crate manufacturer, discusses how the integration of SolidWorks® 3D design software into their engineering process has allowed crating engineers to take sophisticated wood and steel designs to the next level with better 3D representation for their customers and vendors.

Get Clarity

SolidWorks® gives Valley Box crating engineers a tool to accurately communicate complicated crate designs to their customers. “It’s also an impressive presentation tool that can be easily understood by all involved decision makers,” says Alicia Guillette, President at Valley Box.

SolidWorks® 3D wooden containers can be animated to show the build process, moving parts, or view each piece in detail. This clearer communication streamlines the design process assuring both Valley Box –as the crate manufacturer– and the customer is satisfied with the final crate design.

Complex products require complex designs for acceptable protection during shipment. “I like that we have the ability to test the crate design, to identify potential weak points, before it goes into production,” comments Guillette.

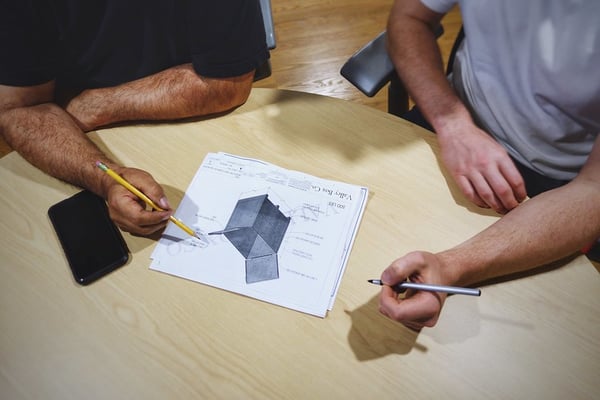

Got .STP files?

Customers who design their products in a 3D environment will find that Valley Box can easily create designs using the customer’s project files.

“This means we can work with long-distance clients because we know the customer’s measurements are accurate,” says Guillette. “We can also send our customer the full 3D model so they can put it into their assembly to ensure proper fitment. Doing this helps to cut down on the number of prototypes and ensures fitment before crate design goes into production,” adds Guillette.

By reducing the number of prototypes Valley Box can keep prices lower and reduce the amount of waste.

About SolidWorks®

SolidWorks applications help millions of engineers and designers succeed. For more information visit http://www.solidworks.com.

About Valley Box Company

Valley Box has been a fixture of San Diego’s crate manufacturer industry since 1965 specializing in tackling design challenges for defense, aerospace, biotech, and commercial applications which include; crating solutions for over-size products, shock-resistant crating for sensitive equipment, structural welding, and effective moisture resistant packing and materials.