Distinguishing your type of manufacturing process can really help guide you to know the best time to start considering your reusable crates design.

Design challenges can be overcome by involving your wooden crate vendor during the early product development phase. To simplify the process Valley Box's crating experts break down manufacturing in to 3 types.

Manufacturing Types

Type 1: Large Daily Quantities

A “type 1” manufacturer would include products that are produced in large daily quantities rolling off an assembly line like thermo-formed plastics or semiconductors. The time to address crating should be prior to any manufacturing.

Treat the reusable crates as part of the product rather than an afterthought. If your product is moved, handled, or staged during production, it may be cost effective to incorporate the wooden shipping crate into your process as a function of material handling.

Type 2: Bulky Quantities

A “type 2” manufacturer may produce a product that has a larger dimension, and the throughput time could range from a week to months like machinery or computerized manufacturing equipment.

The product’s design may be the same or vary to customer requirements, but would generally ship assembled with few ancillary shipping crates. The time to address packing crates should be during the product production phase, in order to avoid shipping delays.

Type 3: Customized Quantities

A “type 3” manufacturer is similar to a "type 2" but may be more customized, like custom conveyor systems or whole production lines. Wooden shipping crate designs are usually addressed once the product is completed as the product may undergo last minute modifications and possible dis-assembly due to various shipping challenges.

Real World Example

In a case study put together by Valley Box we take a look at a Type 3 manufacturer:

An Aircraft Company who manufactures large and heavy milled rings, which require off-site machining by a sub-contractor, who then ships the rings back to the point of origin.

Valley box suggested reusable crates rather than a one-way shipper. The reusable features provided long-term durability and included steel, hardware, waterproofing, and an attached loading ramp.

Assuming a performance lifespan of at least 5 years, the savings of this reusable shipping crate design out weighed the cost of replacing each one-way shipper.

Other benefits included:

- Expedited round-robin shipments

- Reduced waste associated with one-way shippers.

Watch the Video Series

Want to learn more?

Want to learn more?

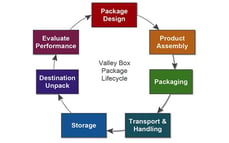

Valley Box created this helpful video series, which walks viewers through the a package's lifecycle.

The pre-recorded webinar starts by explaining the lifecycle and moves into the importance of planning your package design.

Watch this video to learn more!