Corrosion can be a big problem for manufacturers whose products include a variety of ferrous metals (mild/carbon/stainless steel, cast/wrought iron) or non-ferrous metals (aluminum, brass, copper, nickel, tin, lead, zinc). Fortunately, there are a number of effective corrosion prevention solutions that exist which can help with rust prevention. Further, several products can even help remove existing rust or corrosion, restoring parts to their original luster and strength.

Automotive, Electronics, Military, and Oil & Gas industries are effected by corrosion to parts. Its important to remember the types of products and solutions that should be employed will depend on a variety of factors from type of metal to the environment to storage methods. Click Here to learn more about the differences between ferrous and non ferrous metal.

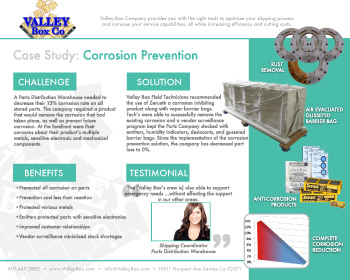

The following case study demonstrates how Valley Box Company helped one manufacturer address their packaging and corrosion prevention and create an anti corrosion plan that reduced parts loss to zero percent.

The Challenge

Rebecca was 4 months into her new position as a Shipping Coordinator at a Parts Distribution Warehouse and could already see that part-loss was a major concern. From her early calculations they were experiencing a 13% damage rate on all stored parts due to corrosion. These corroded parts lead to stock shortages which delayed deliveries and therefore customer relationships and total sales. Rebecca wanted to solve this issue before her next review so that she could prove cost savings to the company. Rebecca reached out to the current packaging provider, Valley Box Company, to see if they could provide help, in a hurry!

The Solution

Rebecca explained the challenge to her packaging rep, Jim Becker, that she not only needed to prevent corrosion but also remove rust that had already developed. She explained that the products had multiple metals and sensitive electronic and mechanical components and figured that this would pose a challenge.

Since Valley Box provided the wood crates Jim already knew the dimensions and weights of the products. However, in order to help develop a solution, Jim needed to know a few more factors that effect corrosion. The subject of primary concern was to prevent the corrosion of any more parts in order to cut the quality issue off at the source. Then they would tackle removing the rust from corroded parts in order to bring them back to a usable condition.

Corrosion Prevention

Regarding the parts without corrosion Rebecca explained that the parts were assembled in a cool dry warehouse, then placed inside crates, then moved to a second warehouse for stock storage until shipment. She said that the stock storage warehouse was open on one side and therefore experienced some temperature extremes and it could possible get "moisture in the air".

Jim asked several more questions to help him zero in on a solution, "How long on average are the parts being stored before, during and after shipment? And do they need to be reaccessed after being packed for storage?" From the moment the part entered the wood crate to the time a customer removed it, the Parts Distribution had no need to open the crate to reaccess the part and this timeline could range from 2 months to 1 year.

Jim suggested the application of a heat sealed Vapor Barrier Bag plus Vapor Phase Corrosion Inhibiting (VPCI) diffusers in order to prevent rusting of parts. The bag would enclose the part 100% the moment it came off the assembly line. Diffusers in the bag would emit powerful corrosion inhibiting molecules that settle on the metal surfaces and protect them from corrosion and are safe for electronics, odorless, non-toxic, and residue free. Below is a video showing how a Zerust diffuser capsule works.

Rust Removers

Moving forward with the project Jim and Rebecca discussed the parts that currently had corrosion. The parts that required rust removal were stainless steel and some alloys, but some of the parts also had coatings, plastics and rubber.

Jim knew just the product that would solve this challenge. He suggested a fast acting Zerust rust remover product which can remove light to medium rust and tarnish, even in cracks and crevices, and is safe to use with paints, rubbers and plastic. The product is simply sprayed onto the part then wiped off with minimal clean up. Better yet the product is non-hazardous to dispose of. This is a video of some of Zerust's rust removal products in action.

Anti Corrosion Plan

Valley Box Field Technicians had several solutions for the parts Distribution Warehouse. Combined, these solutions were the best remedy for the environmental and handling factors in this particular case. Each corrosion prevention solution is unique to the Manufacturer. Valley Box utilized the following:

- Vendor Maintained Inventory program

- Rust Removal products

- Vapor barrier bags

- Zerust—Corrosion Inhibiting Diffuser

Valley Box was able to provide a solution to successfully remove corrosion and prevent rusting. Finally, the vendor surveillance program kept the Parts Company stocked with crates, barrier bags, and anti corrosion diffusers.

Benefits

At her 6 month review Rebecca was able to prove cost savings of the new barrier bag + diffusers. She calculated that it cost less to continue investing in the Anti corrosion Plan than to spend time on reactionary rust removal The benefits of Valley Box’s corrosion prevention plan were numerous. The plan:

- Improved customer relations

- Prevented all future corrosion on parts

- Reduced parts loss to Zero percent

- Reduced cost of labor for rust removal