When it comes to reusable shipping crates, its a no-brainer to minimize wasted time, excessive energy and high costs. Although there's no foolproof approach or packaging solution that can meet every packaging need in the world, you can avoid having your best laid plans going awry by avoiding the common pitfalls when it comes to navigating through the packaging design process!

Detour Ahead: Expect Roadblocks in Advance

Your boss made it perfectly clear that everyone be at work on-time today for an important meeting. You decided to leave 30-minutes earlier than usual, just to be on the safe side, then BOOM—traffic comes to a screeching halt halfway through your commute thanks to an road construction blocking four lanes on a five-lane highway.

There’s no way you’ll make it in time because the highway is now a parking lot filled with angry commuters and honking horns. But you did everything right... right? maybe you should have checked your traffic app to get the 411 before you left, lesson learned.

Take packaging design, for instance. When it comes to creating reusable shipping crates, there are bound to be mistakes. When you skip critical prep work, those mistakes are more likely to happen and the end result is almost always disastrous.

Plan ahead! Know about the critical design elements that go into wooden crates. Download the cheat sheet below!

Abra Cadabra: Disappearing during design process

If you play the disappearing act with the packaging design company you may very well end up with a finished package design that is not what you pictured in the beginning stages. Industrial goods have a lot of variables that need to be met by specific packaging solutions.

If you play the disappearing act with the packaging design company you may very well end up with a finished package design that is not what you pictured in the beginning stages. Industrial goods have a lot of variables that need to be met by specific packaging solutions.

Is your product hazardous, heavy, bulky, sensitive to the elements or all of the above? Will you require saddles, foam, tie downs, or additional blocking and bracing?

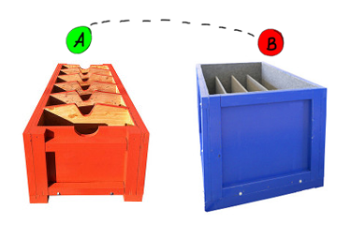

Make sure to keep the communication lines open with the company providing your reusable shipping crates to help make decisions on the best solutions for your product's packaging. Although most exterior boxes are really similar in design, it is what is going on inside that really provides the protection.

Visualization: Know the entire shipment process

Play the entire shipment through from beginning-to-end. Consider how the reusable shipping crates will be:

- packed by your company

- handled by the freight companies

- and ultimately accessed by end users

Watch Valley Box's webinar on improving packaging performance by looking at the packages entire lifecycle. The webinar breaks down the entire shipment process from; Package Design, Product Assembly, Packaging, Transport & Handling, Storage, Destination unpack, and Evaluating Performance. How's that for Visualization?

One Size Fits All: Not all wooden crates are created equal

Sure, some stock sizes might work. Others? Not so much. If you opt for a "one size fits all" solution, your product may be more susceptible to damages from vibration, moisture or abrasion.

The company handling your packaging manufacturing can help you decide if stock sizes are right for you, but if stock sizes just won’t do, packaging should be designed based on specific information about your product.

Giving Up: Search for more ways to save

Never give up! Keep asking questions and learning about your packaging design options. Believe it or not, breakthroughs are as common in the packaging industry as they are in the computer industry. These breakthroughs may mean access to newer and more innovative packaging materials or better processes that can help you save money and reduce costs.

For example, through newer technology, less packaging could actually provide greater package strength and product protection.

- Did you know that reducing the weight of your package typically reduces the shipping costs?

- Materials matter too, the most common types of materials used for industrial packaging include steel, corrugated, wood, and plastic.

- The way you secure your package can offering savings whether with nails, screws, latches, or locking closures.

IDK: Information deficiency

When obtaining a quote, it's so important to have detailed answers about your product. If your answer is "I Don't Know" the supplier may need to quote a higher price (to be on the safe side). When you don’t have your details in order, it's also difficult for the packaging manufacturer to offer suggestions that can potentially save precious time and money.

Read Valley Box's helpful blog post that lists 5 key steps to prepare your product to ship. It lists the steps you should take before picking up the phone and calling your packaging provider.

It's All About the Benjamins: Basing a decision on price alone

Sure, price is often a factor, but it should never be the only factor. This is a good way to make a bad decision about the type of packaging to purchase for your product. Important factors include: product offerings, quality, innovation, delivery costs, on-time delivery, etc.

Before jumping into business with a new packaging provider, there are a few critical questions that should be asked in order to rule out potential challenges later in the working relationship. Follow Valley Box's blog 10 Questions to Ask Before Hiring a Packaging Company or click the download button below.

If you ignore what is truly important in the long run, protecting your product to its end destination, your packaging could end up costing you more down the line. For example, poor quality alone can compromise the safety of your product. If damaged, it will cost more to replace or repair it than it would to protect it in the first place! Check out Valley Box's help guide helping you estimate how much your packaging should cost or click the download button below.