To operate safely, efficiently and profitably, manufacturing companies must invest in the proper material handling equipment. Understanding material handling equipment, the different types, and the role it plays in manufacturing is the first step towards choosing the best equipment for your business.

Material Handling is the movement, storage, control and protection of materials, goods and products throughout the process of manufacturing, distribution, consumption and disposal.

Material Handling Equipment is the mechanical equipment used to increase output, control costs, and maximize productivity. There are many types of material handling equipment including: Custom Fabricated Steel Fixtures, Multi Use Systems, Positioning Equipment, Storage Equipment, and Transport Equipment to name a few.

Multi Use Systems

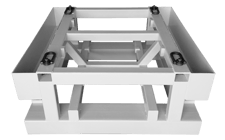

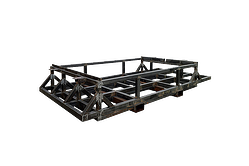

Multi use systems are custom engineered material handling systems. They are often a combination of products integrated to one system. A good example is pictured above: a build stand that is incorporated into the shipping base (top box not shown) to accompany the shipment to a subassembly plant. The custom design reduced the labor spent moving the part from multiple build stands prior to shipment. The design took into account reducing vibration damage from geeral handling and shipping with a floating steel deck attached to a wood base with isolator mounts.

Multi use systems are custom engineered material handling systems. They are often a combination of products integrated to one system. A good example is pictured above: a build stand that is incorporated into the shipping base (top box not shown) to accompany the shipment to a subassembly plant. The custom design reduced the labor spent moving the part from multiple build stands prior to shipment. The design took into account reducing vibration damage from geeral handling and shipping with a floating steel deck attached to a wood base with isolator mounts.

The following are just a few examples of other multi use systems:

Assembly Stand

|

Isolator

|

Product Build Stand

|

Shipping/Handling

|

Staging Stand

|

Rubber-Lined Steel Saddle

|

Custom Fabricated Steel Fixtures

Custom material handling solutions are perfect for assembly lines, warehouses, distribution centers, stock rooms, and anywhere else that moving loads is required. Custom solutions can:

|

|

Valley Box can evaluate your internal operating procedures and help you decide whether a custom material handling solution is right for you.

Positioning Equipment

Poorly positioned products and equipment can be dangerous for worker ergonomics during transport, handling, storage and machining. This may also pose one of the biggest threats to your bottom line. To prevent worker injury and damage to products and materials, consider positioning equipment such as work assembly stands, platforms, and stock pickers. If your needs are unique, again, customization is always a viable option.

Storage Equipment

Shelving, pallets, and storage carts are just a few types of storage equipment that can enhance processes and increase safety. Storage equipment helps reduce or eliminate clutter, organize other equipment and tools, and preserve floor and storage space. When work areas operate efficiently and safely, employees are safe.

Transport Equipment

Transport equipment is equipment used to move material from one location to another, so between workplaces, between a loading dock and a storage area, and more. There are so many different types of transport equipment available you'll lose count. Just a few types include:

|

|