If your facility lacks the proper material handling equipment, things like efficiency and lead times, worker morale and safety, and even the quantity and quality of projects your facility can safely handle can be affected.

Fortunately, if you invest in the right material handling systems for your unique facility, you will increase speed, efficiency and safety. To optimize and simplify manufacturing processes, delivery, set-up, and more consider investing in custom material handling equipment such as multi use systems.

Remember, when your manufacturing processes run smoothly, you can expect an increase in sales which translates to increased cash flow!

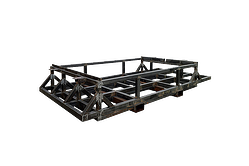

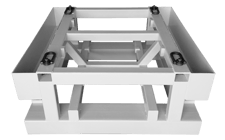

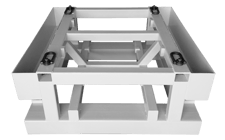

Multi Use Material Handling Equipment

Multi use systems are typically custom engineered material handling equipment. These super-efficient systems combine several products into one unit that can perform multiple tasks. In addition to streamlining processes, increasing speed, and enhancing safety, multi use systems can help preserve precious floor and storage space.

The example above is a build stand that is incorporated into the final packaging for shipment to a sub assembly plant. The experts at Valley Custom Fab’s build can help solve many manufacturing challenges. Their solutions range from:

Staging Stands

|

Assembly Stands

|

Product Build Stands

|

Shipping/Handling Stands

|

Other Types of Material Handling Equipment

Steel Fabrication

When it comes to safety and time savings, steel fabrication has you covered. Just a few fabricated applications include steel reinforced boxes and canted cradles. Steel fabricated applications such as these help:

- Extend reusability

- Enhance internal strength

- Simplify production processes

Add customization, and safety and time savings are significantly enhanced. Whether you’re looking for steel fabricated applications for your assembly line, warehouse, distribution center, stockroom, or anywhere else moving loads is required, Valley Box has a Certified On-Site Welding shop that can customize your solutions.

Positioning Equipment

Objects and materials that are poorly positioned for transport, handling, storage and machining can be dangerous for workers and your businesses’ bottom line.

Objects and materials that are poorly positioned for transport, handling, storage and machining can be dangerous for workers and your businesses’ bottom line.

To prevent worker injury and damage to materials, consider investing in positioning equipment such as work platforms, assembly stands, and stock pickers.

Storage Equipment

Shelving, pallets, and storage carts are just a few types of storage equipment that can help improve your manufacturing process. Storage equipment helps:

Shelving, pallets, and storage carts are just a few types of storage equipment that can help improve your manufacturing process. Storage equipment helps:

- Preserve floor and storage space

- Organize other equipment and tools

- Keep the work area safe by reducing or even eliminating clutter

Storage equipment can be ready made or made to order. Customization can further enhance the benefits of storage equipment because each piece is made according to your exact specifications.

Transport Equipment

For worker safety, efficiency and speed, and to prevent damage to equipment, everyone in manufacturing should be using transport equipment. Just a few popular types of transport equipment include:

- Ergonomic material handling carts (ergo-carts)

- Hardwood platform carts

- Heavy duty cradle carts

- Utility carts and dollies

While transport equipment is available in all shapes and sizes, you can also have your equipment custom made for unique uses, increased comfort, and to help simplify operations.