If you think all materials are created equal, think again!

When designing a shipping crate, material selection is key to obtaining an end result that both you and your customers will be happy with. Valley Box is a crate manufacturer that knows what it takes to create shipping crates that are strong, stable and sustainable.

All Wood Crates are not created equal

Lumber

Valley Box's number one choice for wood is Grade 2 Douglas Fir. This wood is known for strength and stability, and it has limited knots and defects, yielding little scrap (making most of the wood usable for construction).

Plywood

Valley Box uses several types of plywood ranging from Marine grade, ACX and CDX. Plywood thickness can add considerable strength to the package especially if you move up in size from 1/4" to 1/2" to 3/4" all the way up to 1" thick!

Valley Box always places plywood with the grain running vertically which adds to the shear strength of each panel.

Download our Wood Grades Guide to learn more about the different wood grades.

Materials Inside the Shipping Crate

Even the best materials require reinforcement. To enhance high-grade wood crates, the crate manufacturer may incorporate internal components or “internal technology”.

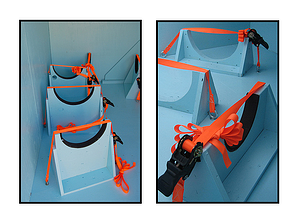

Saddles and Tie downs

Saddles and tie-downs are custom-shaped to the product at specific locations where the customer's part can be supported.

The tie-down and saddle can be loaded and unloaded for repeat use and reduce packing errors by personnel.

Saddles can be constructed from materials such as corrugated, wood, and steel (all of which can be recycled).

Cushioning

Cushioning from materials such as foam, carpet, or neoprene can prevent damage during transit such as:

- Abrasion

- Vibration

- and Shock

Valley Box can custom install many types of cushioning to meet customer product needs.

Blocking and Bracing

Blocking and bracing is a technique used to secure a part inside the crate.

Crate manufacturer's pack crews will screw or nail pieces of lumber in place around the part. This will reinforce the part's position in the crate.

Blocking and bracing also help to support the integrity of the packaging from the inside out!

Materials Outside the Shipping Crate

While internal components can help to immobilize your product during transit, external materials can make a crate easier to handle and identify, less susceptible to water damage, and even longer lasting! To enhance high-grade wood crates, Valley Box may incorporate external components or “external technology”.

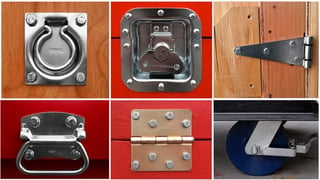

Hardware

Hardware can help make a wood crate easier to lift or open. It can improve employee access to the inside or aid in moving the box around your facility.

Such hardware may include casters, handles, hinges, eye bolts, lag screws, lifting rings, screws, and courtesy nails.

Almost all hardware is available with special treatments such as galvanization in order to better withstand corrosion.

Coatings

Coatings such as paint can help reduce damage from moisture and UV rays which in turn will extend the life of the crate.

Paint adds ultraviolet protection to any wood box which, if you haven't heard, blocking damaging UV light increases a surface's lifespan... significantly!

Not to mention Valley Box customers have found that painting their wood crates can aid in container identification whether it be in their own yard, a trade show convention loading dock, or on the back of a delivery truck.

Stencils

Crate manufacturers use stencils that can be used to display your company logo, part numbers, special handling and other instructions, and chemical notices.

Stenciling can be applied with pigments that spray, brush, or stamp onto the surface.

Learn more about How Stencils Are Made.

Poly Stretch Wrap

The poly stretch wrap helps to ensure that the bursting strength of the packaging is properly reinforced.

Stretch wrap is a poly product with stretch qualities to allow a snug tight fit around products with limited risk of damage due to too much tension.

Steel Banding

Steel banding also helps crate manufacturers reinforce the bursting strength of packaging.

Steel banding has no stretch qualities and requires a tool to tighten and then crimp off the secured ends.

Valley Box uses these and other components to create custom wood crates.

Read the Crate Design Cheat Sheet which provides additional details about the many different parts of wood crate design.