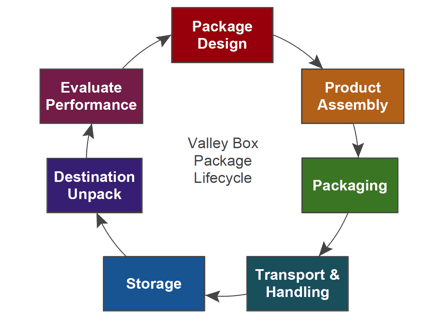

Valley Box Company, a San Diego crating manufacturer, welcomes you to this 7-part series exploring the package lifecycle with a focus on matching you with the right packaging method for your product.

You have a few options moving forward.

- Voracious Reader: Below you'll find a blog-transcript of this fifth section in the Package Lifecycle.

- Press Play: If you want to sit back, relax and let us do the talking watch the video of the presentation below!

The next step in our packaging lifecycle is Storage, which pertains to the overall length of time your product will be kept in its packaging.

For the purposes of this series, “Storage” pertains to the time span that a package can survive and protect products from atmospheric conditions.

For example different products require different means of protection

- Electronics or Machinery manufacturers protect their products from potential-short-term surface corrosion that can degrade performance or longevity.

- Part Distributors require long-term-protection since the storage timeline can be unknown due to unpredictable demand..

- Bio-tech and Perishable products often require short-term temperature-controlled packaging, to avoid damage or spoiling.

Case Study

Both the domestic and overseas shipments were packaged the same;

- with expanded polystyrene, or EPS, containers

- and four 8 oz. coolant gel packs to maintain an ambient temperature for 72 hours

Investigation: By tracking test shipments and reviewing shipping records, we found that the domestic shipments typically arrived in 48 hours in good condition; while the international shipment took twice as long to arrive. It turned out the EPS containers were not suitable for shipments that exceeded 72 hours.

Solution: The temperature issue was resolved by switching to a water-blown-polyurethane-foam or PUR container, which has almost double the insulation capacity of the same size EPS container.

Outcome: The PUR container successfully reduced damage claims of all international shipments to zero. The benefit from eliminating damaged proteins out weighed the increased cost of the new PUR container.

Preventing Corrosion

As San Diego crating experts let’s talk about preventing surface corrosion during storage. There are many products available that can either

As San Diego crating experts let’s talk about preventing surface corrosion during storage. There are many products available that can either

- Emit corrosion inhibiting vapors into the product air space in a package, or

- Absorb moisture within a sealed package

- Completely cover the product surfaces with a protective coating

The type of protection used for your particular product would require some analysis based on the conditions stated earlier.

Packing Tips

Here are some packing tips to reduce the chance of corrosion developing during your packaging phase.

- Clean and Dry parts before packing

- Wear clean dry gloves when handling metal parts

- Avoid direct contact of metal with packaging material such as; wood, paper or cardboard

- While packing, the temperature of the parts should be the same as the current room temperature

- Seal packages with heat sealing or waterproof tape

Anti-Corrosion Case Study

Here we come to a Military parts distribution warehouse that was experiencing a high rate of surface corrosion on stored parts.

Challenge: They were in desperate need of a solution for a product that would not only prevent rust during storage, but would remove existing corrosion that had taken place.

Solution: Valley Box implemented a Corrosion Prevention Plan that utilized Zerust® rust removal products to successfully remove all corrosion. A variety of emitters and desiccants were used in concert with vapor barrier bags to eliminate all incidences of corrosion.

- A yellow drawer liner is a non-toxic, recyclable, ferrous polyethylene film that can be placed into storage drawers for metal parts.

- The custom sized green bag contains corrosion inhibiting technology and protects both ferrous and non-ferrous metals.

- A yellow capsule emits powerful corrosion inhibiting molecules which settle on metal surfaces, protecting the parts from corrosion

Watch more of the series

- Packaging Design - Watch the Video - Read the Blog - View the Slideshow

- Product Assembly - Watch the Video - Read the Blog - View the Slideshow

- Packaging Process - Watch the Video- Read the Blog - View the Slideshow

- Transport and Handling - Watch the Video - Read the Blog - View the Slideshow

- Storage - Watch the Video - Read the Blog - View the Slideshow

- Destination Unpack - Watch the Video - Read the Blog - View the Slideshow

- Evaluation of Performance - Watch the Video - Read the Blog - View the Slideshow