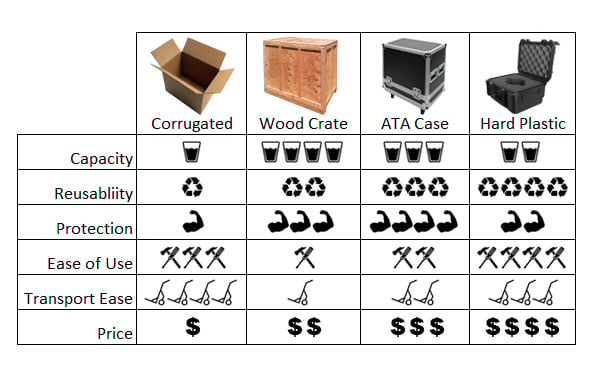

Every packing material has its strengths and weaknesses. It's important to understand the characteristics of all packaging in order to ensure your product's protection during transit.

Heard enough?! Ready to start talking about your project?

Corrugated, wood and plastic are just a few packaging materials. All three are popular in the world of packaging and shipping, but they have distinct advantages and disadvantages.

Let us compare the materials used in popular packaging styles, including cardboard boxes, wood crates, ATA cases and hard plastic cases, then you can decide which one will work best for your next big packaging project.

Corrugated Box

Cardboard has carved a very special place in packaging industry, as it is used to help transport trillions of dollars worth of goods each year. As popular as cardboard may be, it still has some stiff competition—wood and plastic

Pros:

- Accessibility is universally known (everyone knows how to open a card board box)

- The packaging itself is lightweight

- Easy to handle during transport

- Can be environmentally friendly

- Low cost compared to other packaging materials

- Not weatherproof

- Can not support very heavy payloads

- A basic cardboard box can be reused just a few times before the material will degrade

- Offers little in the way of protection from rough handling with additional cushioning

Wood Crate

Contrary to popular belief, "wood is as an hygienic packaging material as plastic," according to a study conducted by a group of researchers at the Faculty of Science and Technology of the New University of Lisbon.

The group “analyzed the most common micro-organisms in plant products that may contaminate the container, or those resulting from normal handling and storage, such as Enterococci, Escherichia coli, Clostridium perfringens, Pseudomonas and Bacillus cereus."

“Having determined the bacterial concentration at different temperatures,” says the report “it was concluded that there were no significant differences between the bacterial load of wood and plastic.”

Pros:

- Easy to customize

- Eco-friendly

- Easy to repair

- Cost less than ATA and hard plastic cases

- Can support the heaviest payloads

- Offers very high protection due to customized internal components

Cons:

- Require lifting equipment (pallet jacks, forklifts, or cranes)

- Finished wood crates are heavy

- Employee handling concerns (splinters, requiring tools to get inside)

- Phyto Sanitary Export requirements such as heat treating

ATA Case

Also called road case, roadie case, or flight case, an ATA (Air Transport Association) case, is a shipping container specifically built to protect audio and lighting production equipment, film and video equipment, musical instruments, gear, or other delicate equipment during transit between locations—especially airports.

Pros:

- Easy to customize

- The ease of use is very straight forward

- Transportation is easy due to limited lifting equipment requirements

Cons:

- Expensive they have a higher price point than wood and corrugated

- Can transport moderate to heavy payloads

- Cannot be disassembled and rebuilt like wood crates

- Internal Components are not easily repairable

Hard Plastic Cases

Plastic cases (aka thermo-molded, injection molded cases, high density, hard blow molded) are known for being lightweight, weather-resistant and reusable. However, plastic crates have a few disadvantages over wooden crates.

Pros:

- They are easy to move around

- Good choice for items that are lighter and not as fragile

- Fire safety ratings

Cons:

- Cannot be disassembled and rebuilt like wood crates

- Difficult to customize (as it takes longer to mold a crate out of plastic)

- Are not easily repaired

- Degrade over time due to light, denting, cracking and scratching

- Not biodegradable

In the end, all types of crates offer important benefits and drawbacks. The type of crate you ultimately choose will depend on the contents, climate, costs and more.